You need it. We’ll do it.

With our many years’ experience in pharmaceutical processes, in plant engineering and construction for fluidised bed and pan coating, for wet granulation as well as associated product handling, we offer our customers a wide range of services in which the various areas complement one another perfectly.

Development and design

Customised development is our core field of expertise. Our work focuses on requirements such as- Increasing efficiency, e.g. through cleaning-optimised design

- Greater availability

- Simplified and cost-effective maintenance

- Improvement of handling and/or ergonomics

- Compliance with current regulations

The following are typical of the XERTECS service portfolio

- Development and optimisation of individual sub-assemblies or complete plant

- Design and complete plant layout in 3D

- Inclusive of detailed specification of all required semi-finished parts and purchased parts

- Prototype manufacturing

- Arranging the cost-efficient manufacture of our designs

For us, allowing for country-specific standards and regulations or customer-specific suppliers is a matter of course, as is the cost-effective integration of components or partial solutions already available on the market. In the process we co-operate with well-known manufacturers of individual plant components or sub-assemblies.

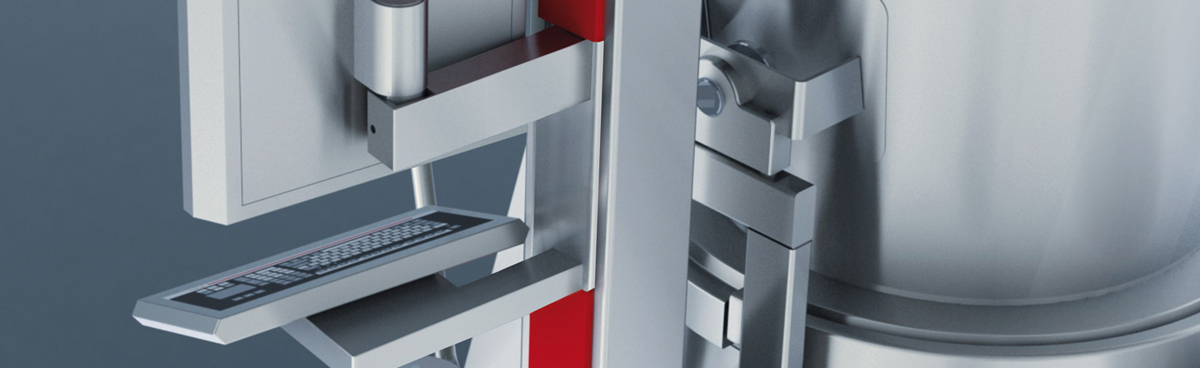

Design

We are firmly convinced that high-quality technology and perfect handling must also be demonstrated in the ambitious design of a solution. That’s why we never leave visual appearance and ergonomics to chance but cultivate close co-operative links with professional industry designers who have appropriate experience in our market segment.

Process optimisation

The manufacture of pharmaceutical products is complex and expensive. Process expertise is therefore often more important than the mere performance characteristics of a machine. XERTECS staff have many years’ experience with all pharmaceutical processes, in particular fluidised bed and wet granulation, as well as in the coating of particles, pellets or tablets – in fluidised bed or pan coating. This expertise is always incorporated into our own developments but is also available for the optimisation of existing machines, e.g. in the area of spray nozzles.

Control systems and automation

Control systems are critically important in the manufacture of pharmaceutical products. They serve not only to safeguard the product, personnel and the environment, but also ensure efficient production documented in line with regulations. XERTECS’ expertise covers- Control systems complying with current GAMP guidelines

- Data back-up and access authorisations in accordance with FDA Guidance Document CFR 21 Part 11

- Expertise in explosion protection in the case of defined dust and/or solvent zones

- Solutions for connections for MES-Systems

- Simple, clearly structured solutions even for complex problems

For us, allowing for customer-specific solutions when it comes to hardware (e.g. Siemens, Allan Bradley, Mitsubishi) is just as much a matter of course as the use of different software solutions, for example Wonderware or Zenon.

Documentation

Correct documentation is a natural component of our work. We take into account all relevant national as well as international requirements such as, for example, GMP, GAMP, CE, ATEX or UL. In addition, when the development is concluded, all required documents are handed over.

Service

Comprehensive and customer-focused service provision is a substantial and integral part of our portfolio. It includes, among other things- Support for installation, commissioning, validation and qualification

- Expert’s reports on safety

- Optimisation solutions for existing machines and processes

- Retrofits, maintenance and spare parts.

The services we provide are naturally also available to customers with plant supplied by third-party manufacturers.